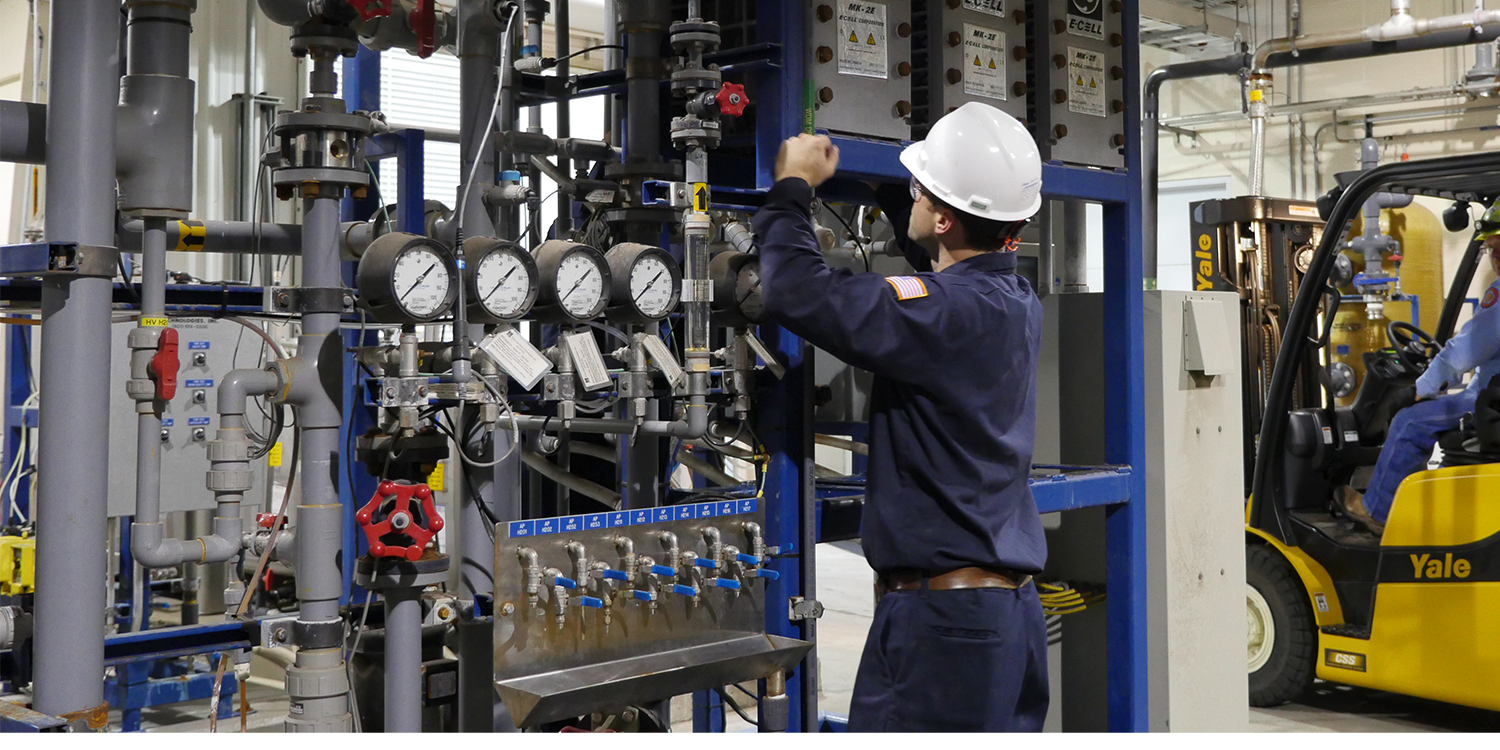

EDI Equipment (Electrodeionization)

Veolia E-Cell EDI Systems

The E-Cell electrodeionization product line is designed to remove residual salts and ionizable aqueous species (such as carbon dioxide, silica, ammonia, and boron) from your water sources. The E-Cell line uses electrical current to provide ultrapure water to meet today's most demanding ultrapure water applications.

EDI is a safe and environmentally conscious water treatment solution, especially as a substitute for more traditional ion exchange resin solutions. EDI brings advances in both energy and operating expenses to the ultrapurity water treatment train. EDI requires no regeneration chemicals which simplifies environmental, health, and safety concerns while reducing chemical costs in the process. EDI has no hazardous wastewater discharge and wastes can be easily recycled without neutralization systems needed for ion exchange. EDI operates continuously which minimizes the risk of breakthrough seen with exhausted resin, and it simplifies operations by eliminating the need to take a system offline for regeneration. EDI also reduces facility requirements by having a smaller footprint and lower height requirement than ion exchange, particularly when including supporting equipment such as chemical dosing systems.

Veolia E-Cell EDI systems are ideal for multiple applications including: power generation for boiler and turbine feed water, steam generation and NOx control, microelectronics production, rinsing of semiconductor chips, solar panel production, light and heavy industrial ultrapure process water, food & beverage, and pharmaceuticals.

- Flow rates: 7.5 to 28 gallons per minute per stack

- Up to 97% water recovery

- Requires no acid or caustic chemicals for regeneration

- Requires no brine injection or concentrate recirculation

- Creates no hazardous wastewater discharge

- Applications include: Light and Heavy Industrial, Power Generation, Food & Beverage, Semiconductor and Microelectronics, Cosmetics, and Pharmaceuticals

PRO E-Cell Series RO-EDI Systems

The PRO E-Cell is a line of integrated high purity reverse osmosis and electrodeionization systems. Veolia has brought together two of its platform systems - PRO Series reverse osmosis (RO) and E-Cell electrodeionization systems (EDI) into one treatment solution. Designed for ultra-pure make up water, the PRO E-Cell is built on a single skid with one controller. With versatile configurations and full automation, PRO E-Cell designs offer customers installation simplicity, ease of operation, and up to 40% smaller footprint saving on capital expenses and reducing operating costs.

- Flow rates: 50 to 200 gallons per minute

- Single-source supplier for RO membranes, EDI stacks, and completed system provides enhanced system reliability

- Directly connected RO and EDI system eliminates need for RO permeate storage, pumping, and filtration before the EDI unit

- Automated flow control for RO and EDI using energy saving variable frequency drives (VFD)

- Single PLC and HMI providing one central interface with the system

- Ethernet communication and internet connectivity for remote monitoring and afterhours diagnostics and troubleshooting

- Automated startup sequence and shutdown flush sequence ensures long term performance of EDI stacks and reduced cleaning of RO membranes

- Integrated RO/EDI systems for 40% smaller footprint compared to separate two pass RO skid, buffer tank and pump systems, and EDI skids

- Directly connected and pre-piped RO and EDI reduces capital expenditure, installation complexity, and footprint by eliminating pump and storage components

- Integrated control system further reduces technical skill and time required for installation, commissioning, and operation further reducing costs

- Eliminates bulk acid and caustic environmental, health, and safety concerns associated with aging ion exchange systems

- Applications include: Commercial and Industrial boiler feed water, process water, and gas turbine makeup water